Manufacturer to Machine: Advantages of Direct Bearing Purchases

In the intricate world of machinery, where every small component plays a pivotal role in ensuring seamless operations and enhanced productivity, bearings emerge as unsung heroes, quietly contributing to the life and functionality of various machines.

The journey from a manufacturer to a machine is one that encompasses various routes – a straight path of direct purchase or a winding road through intermediaries.

The discourse that follows aims to spotlight the manifold advantages that nestle within the concept of direct bearing purchases, weaving through the technicalities and strategic underpinnings that define the dynamics between manufacturers and machines.

The Quintessential Role of Bearings

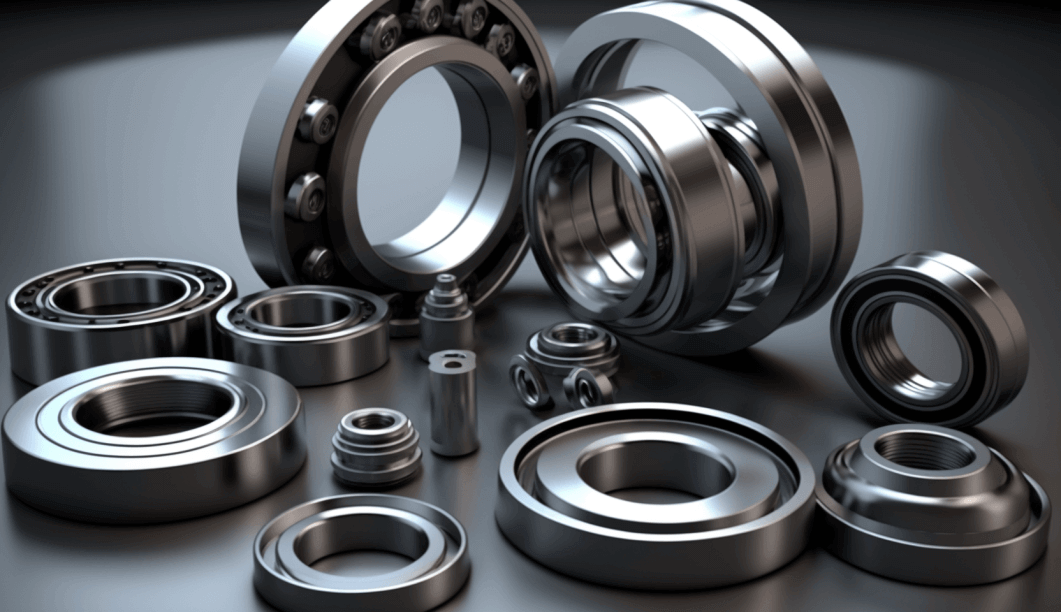

Bearings, in their myriad forms and applications, silently orchestrate the harmonious functioning of machines, reducing friction, managing loads, and ensuring the operational longevity of mechanical devices.

Their criticality is manifested across various machinery and applications, embedding them as integral components that safeguard efficiency and optimize performance. From automobiles to industrial machinery and everyday appliances, bearings find their place, ensuring smooth, frictionless movements and enhanced durability, thereby demanding a meticulous and strategic approach towards their procurement and application.

Navigating Through Traditional Procurement

Traditionally, the procurement process of bearings has traversed through a series of intermediaries, each marking a point in the complex web of the supply chain.

From manufacturers to distributors, wholesalers, and finally, to the end-users – the bearings navigate through multiple channels, often accruing additional costs and encountering potential quality degradation risks along the way.

This process, while established, introduces an array of challenges, such as increased lead times, added costs, and the occasional risk of receiving subpar products, thus sparking the discourse towards an alternative – direct purchasing.

Direct Purchase: A Tapestry of Advantages

Elevating the procurement strategy by directing it towards the manufacturers unravels a tapestry of multifaceted advantages. Economical benefits are conspicuously present, eliminating middlemen, offering potential bulk purchase discounts, and often, ensuring more competitive pricing.

The assurance of authenticity and quality is invariably higher, as direct dealings with manufacturers ensure adherence to quality standards, with product warranties and guarantees often serving as added cushions of reliability.

Tailoring products to meet specific requirements becomes feasible, fostering an environment conducive to collaboration, direct feedback, and customized designs. Furthermore, logistical efficiency is enhanced, marking a significant reduction in lead times and ensuring efficient handling and delivery, thus optimizing the entire procurement process.

Imbibing Real-world Narratives

Peppered across the industrial spectrum are numerous narratives where direct purchases from manufacturers have culminated in tangible benefits, both operational and financial.

Industries, varying from automotive to heavy machinery, have found solace in the reliability and authenticity that direct purchases offer, ensuring their machinery is bestowed with top-tier components, enhancing their life and efficiency. These case studies serve not just as testimonials but as tangible evidences, illustrating the palpable benefits that direct purchases offer in various practical applications.

Tackling Challenges with Strategy

While the advantages are prominent, it’s imperative to acknowledge the potential challenges that may weave through the path of direct purchasing. Potential drawbacks, such as minimum order quantities, logistical challenges, or navigating through international trade laws, might emerge along the way.

However, with strategic planning, developing a robust vendor-client relationship, and a meticulous understanding of international trade norms, businesses can mitigate these challenges effectively, ensuring the path, while occasionally bumpy, leads towards a destination of strategic, operational, and financial success.

Legal, Ethical, and Future Perspectives

Navigating through the world of direct purchasing mandates adherence to trade and export laws, ensuring that the procurement processes remain ethically sound and compliant with international norms.

Furthermore, as the industry evolves, embracing upcoming innovations and technology-driven procurement processes becomes imperative. Sustainable manufacturing and eco-friendly practices are steadily gaining prominence, thereby weaving through the future narrative of bearing manufacturing and procurement.

Concluding Thoughts

As we tether the ends of this exploration, the overarching narrative emphasizes the profound impact that direct purchasing from manufacturers can have on businesses, embedding within it strands of cost-effectiveness, quality assurance, and strategic alignment.

This trajectory, while marked with its challenges, offers a path that, when navigated with foresight and strategic prudence, can guide businesses towards a future where their machinery is not just operationally optimal but is also a testament to strategic, innovative, and ethical procurement practices.

Partnering with platforms like business.emechmart further amplifies this vision, offering businesses an avenue to seamlessly and effectively engage with reputable manufacturers, setting the stage for collaborative success and industrial advancement.